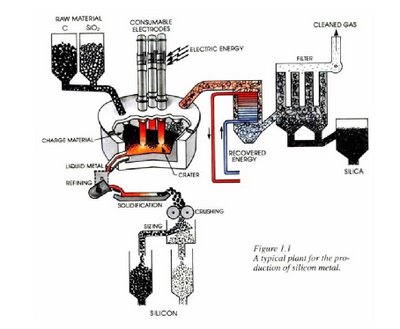

This is a pictoral description of the typical industrial scale process used for metallurgical polysilicon production by Carbothermic Arc Reduction. Most common application of the output of arc reduction of silica to form polysilicon, is for aluminum and steel metal alloying feedstock.

But with care in the selection of the quartz silica and carbon raw material purity and in details of the furnace operation and materials postprocessing, this process is used for the feedstock for subsequent refining to produce solar grade polysilicon. It is apparent that Arc Reduction of silica, is an an energy hog, as one can observe in the furnace picture below.

Solar grade silicon, although presently capacity constrained, is not subject to exactly the same hard limits as electronics grade poly, especially since the logistics of capacity increases for solar grade are not nearly as arduous nor as capital intensive as electronics grade polysilicon capacity. Although solar grade silicon still requires unusual care in the materials production, it is vastly simpler than electronics grade polysilicon production.

This - carbothermic arc reduction of silica - is how the bulk of solar grade polysilicon used by Qcells - the worlds largest manufacturer of silicon photovoltaics, is produced and similarly solar grade polysilicon for the up and coming Evergreen Solar, a new strategic partner with Qcells .

As a process engineer, one can be curious as to how one might improve energy efficiency of this relatively old method of electrical arc chemical reduction of silica to form polysilicon might be improved upon ??? Evergereen is doing some of this, but are there even better ways??

One the face of it, one can observe that the repeated heating and cooling from the reduction remelting, followed by cooling, then pulverizing, then recasting (heating and cooling) then slicing and then diffusion doping with heat once again to make actual silicon solar cells, is not the best EROI one might envision in an optimized silica to solar cells process.

This is a picture of a massive CarboThermic Arc Reduction Furnace owned by Elkem Silicon of Norway. Input is silica quartz, oxygen and ultrapure carbon and graphite. Apparently there are a number of arc reduction furnaces of comparable size in Elkem's inventory.

This is a picture of a massive CarboThermic Arc Reduction Furnace owned by Elkem Silicon of Norway. Input is silica quartz, oxygen and ultrapure carbon and graphite. Apparently there are a number of arc reduction furnaces of comparable size in Elkem's inventory.

The quartz silica feedstock for Elkem silicon's efforts must be unusually pure to permit the use of the relatively crude metallurgical grade arc reduction process to be successfully used for subsequent refining of solar grade silicon. Elkem is a major provider of metallurgical grade silicon to the PV and electronics industries, but it is all further refined by companies like REC, Wacker, and Hemlock before moving on to electronic products.

Q-Cells has purchased its silicon primarily from REC. Evergreen and EverQ also purchase most, if not all, of their silicon from REC (though Evergreen was buying from MEMC until last spring, when MEMC pulled the rug out from under them). Considering that REC holds a 15% stake in EverQ, this is likely to be a durable supply relationship.

The best in the world for ultrapure mined silica feedstock suitable for solar grade polysilicon production seems to be mined at this very beautiful location on the Tysfjord in Norway. The mining operation, with its low cost chemical purification of the raw mineral silica feedstock, is impressive for its attention to detail and the purity of the large deposit of excellent quality quartz pegmatite.

This page shows some interesting pictures of the mine and the manufacturing of the solar grade silica powder. It does not describe methods to purify the powder, which despite the excellent mineralogy of the TysFjord Pegmatite Silica ore, is likely to be chemically treated to optimze the reduction of impurities needed for best in class solar grade polysilicon, at very modest cost increase.

One can envision that this mine provides most of the raw material for Elkem's furnaces, which then ships massive quantities of polysilicon to silicon refiners for solar grade and electronics aspplications.

NOTE updated with input from ALAN on Sept 11 2006

Addendum Dec 9th 2006 - Here are some links to the vistas of the Tysfjord - mountains, maps, and unusual pictures of Orca killer whales inhabiting the fjord itself. Beautiful amazing pictures, not far from the quartz pegmatite mines.

a suspended walkway over a streampictures from an Orca whale watching tour shipamateur photos from a snorkeling tour of the fjordmore of these tour pics with incredible closeups of Orcas in the Tysfjordmaps and more local pictures of a fishing village in summer and winter

wendmansolar+powersilicon+waferscalisolar

solar+cellsphotovoltaicnanosysSunpower

konarkaCyriumNanosolarMiasole powerfilm

DFJNEAJurvetson Heeger

Alivisatosquantum+dotquantum+dot+solar+cellsnano

nanotechnanotechnologyglobal+warmingrenewable+energy

clean+tech